Typically, surplus stocks in slow moving items always show up on a firm’s radar as hogging shelf space, dragging down sales, and gross profits. On the other hand, there are celebrations around better moving products and ‘sold-out’ becomes a matter of pride.

Actually, when sold-outs or stock-outs or shortages happen too early in the season, then it is not really a reason to celebrate, because you are not capitalizing enough on the sales opportunity in the better moving product. OOS or out of stock situations can harm sales.

Impact of surpluses in slow movers is clearly felt in discounts needed to liquidate them or in goods returned value or in cost of extended credit period to the market. These are costs easily measured as a numerator on sales value and quantified.

But one must pay attention to cost of missed sale opportunity. This one focus can surely improve sales.

Question is how to measure the impact of these shortages or stock outs?

For this, we need to see how many days there was a ‘OOS’ (out-of-stock) situation and apply the probability that product would have sold, had it been in stock.

Using heuristic methodology, one can calculate ROS (Rate of Sale), further qualify it by weekday versus weekend if that has a significant impact on sale, or by seasonality. This ROS when applied on OOS days to TIL: target inventory level can be used to calculate lost sale opportunity.

Let’s take an example of 3 weeks (ideally a much longer period of time is safer) and plot sales over these 3 weeks where the sales quantity was 14 pieces. One would calculate rate of sale per week as given in below table.

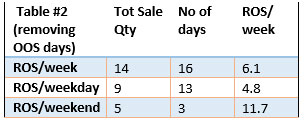

But in reality, there were OOS (out of stock) days that occurred in above 3 weeks, say 5 such days. When you remove the OOS days, the table looks like this:

The ROS figures look improved in table #2. The ROS can be applied to better moving products on their OOS (out of stock) days till the end of season to calculate the upper boundary of lost sales opportunity. I am qualifying this statement because one must acknowledge the ‘substitution’ effect where unavailability of one product does not necessarily lead to loss of sale; instead, only replacement of sale.

Choice of substitute could be influenced by brand loyalty, category features within which another choice is made, how much effort consumer has to put in to find a substitute and so on. However, on a better moving product, one can fairly assume better chance of selling had it been in stock. And, the danger of substitution of sale lies in the probability that consumer could replace your product with that of the competitor!

The lost sale opportunity can be addressed by smarter distribution method, to begin with. By arranging the supply chain in a manner than nullifies demand-side variability by holding inventory at a vantage point and making frequent replenishments to sale points that move the product, OOS days can be much improved. Further, agility in Production function will aid to curtail the lost sale opportunity to a significant extent.

With ‘Pravah’, our supply chain transformation solution, you can build an agile and responsive supply chain from Production to Distribution.

Write to us if you’d like to learn more.

October 5, 2021

October 5, 2021